Winding without Cores

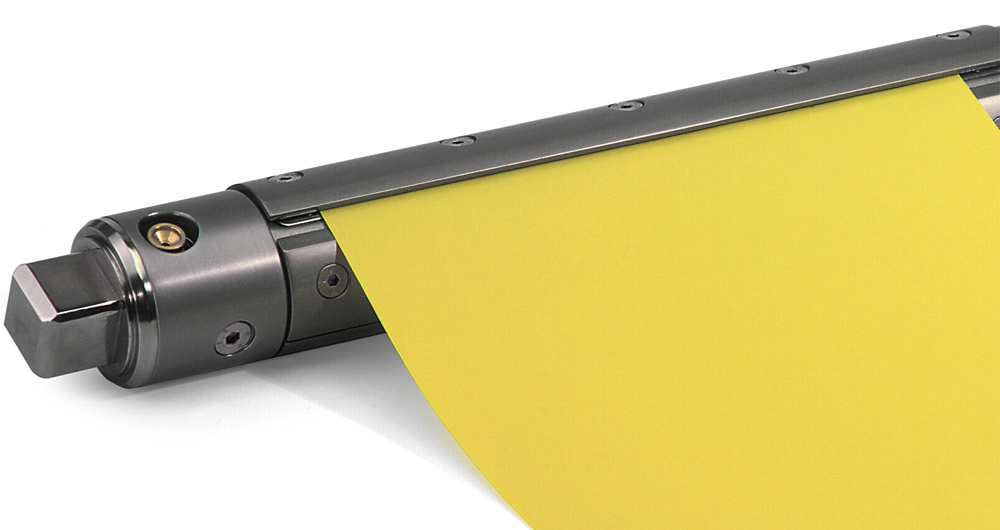

Winding without a core is interesting for many products for purely economic, but also ecological reasons of waste avoidance. After inserting the beginning of the web into the appropriately dimensioned gap, compressed air is applied to the shafts.

The material web marked “Folie” in the functional sketch is clamped and the remaining trays go into the expanded position. The winding process begins and the core diameter of the roll is formed by the expanded diameter of the shaft. When the winding process is finished, the clamping gap is released when the shaft is vented and the material is pulled down or pushed off.

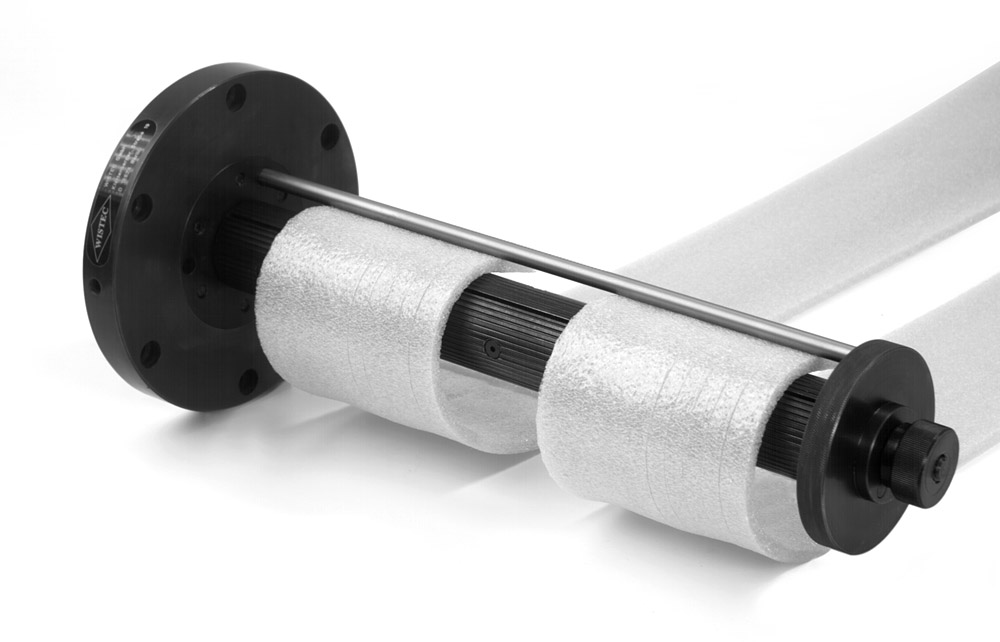

We have also developed solutions for bulky materials: