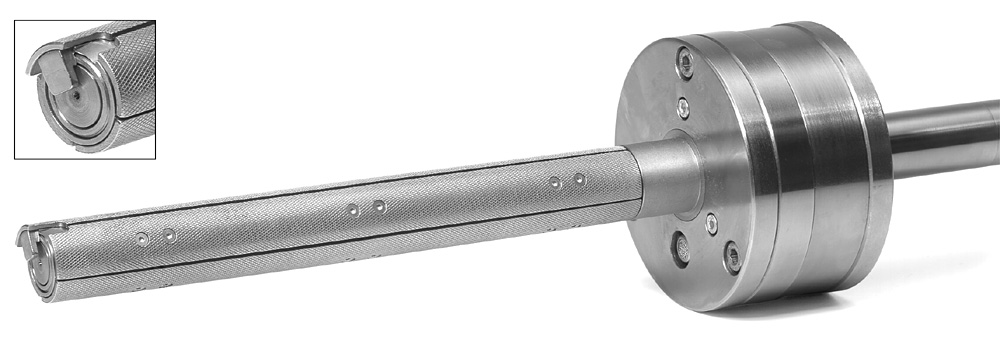

Pneumatic-Mechanical Shafts

Winding shafts based on the pneumatic-mechanical clamping principle combine the advantages of mechanical expansion shafts with those of pneumatic expansion shafts. On the one hand, they guarantee 100% concentric running of the roll, on the other hand, they can be tensioned and released quickly and without effort by means of pneumatics.

The use of pneumatic-mechanical winding shafts can significantly increase the safety of a plant. If the pneumatics are only needed to release the system, there can be no danger and quality problems even if the pneumatic auxiliary energy fails. During operation the roll is safely tensioned without external energy due to spring force (see drawing).

Special designs of pneumatic-mechanical shafts are also used for coreless winding of coils. Here, the absolutely concentric running at any diameter is convincing.

Attachment adapters with a pneumatic-mechanical operating mechanism are also possible. In addition to the above-mentioned advantage of the centric sleeve adapter, sufficiently high clamping forces can be achieved even with narrow designs.

Advantages of pneumatic-mechanical clamping shafts:

– they clamp 100% centrically

– larger expansion paths can be achieved

– Higher clamping forces are possible

– The option of “permanently spring-loaded clamping – compressed air only used for unclamping” (see drawing) means that

safety clamping elements can be built, e.g. for use as robot grippers