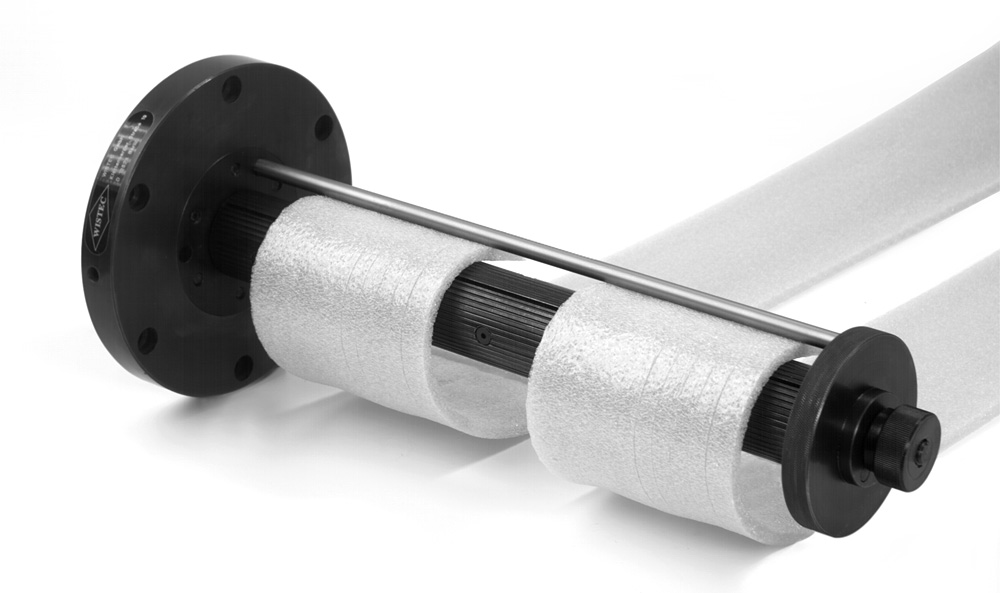

Air shafts pneumatic clamping with leafs (LEAF Type)

The design of a shaft with clamping shells is characterized by the fact that the clamping force is transmitted by means of shells located on the outside. The continuous leafs made of steel or aluminium expand by a central hose. The clamping force thus acts almost uniformly over the entire inner circumference of 360°. This prevents deformation of the cores, especially with thin walls and narrow partitions.

The leaf shaft is the preferred shaft type, which can also be used for coreless winding.

The operating principle is as follows: The web material is inserted into the gap between a gripping lamella under a fixed leaf. When compressed air is applied, the beginning of the web is clamped firmly, while the other leafs expand. When the winding process is finished, the leafs return to their nominal diameter when the shaft is vented. At the same time the web start is released and the reel can be pushed off the shaft.

The following solution has proven to be very useful for clamping very voluminous materials, and with widely varying thicknesses: The beginning of the web is clamped between the expanding clamping shells and a fixed element (bar). Different positions can be selected for the bar.