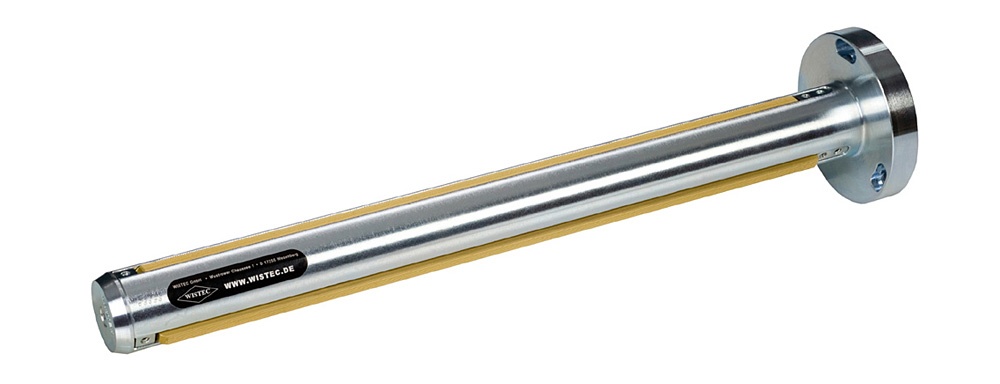

Air shafts pneumatic clamping with clamping bars (SLAT Type)

Winding shafts with continuous tensioning strips have a single hose under each expansion strip. This makes them service-friendly and easy to maintain.

WISTEC Slat-Type shafts are available for any desired diameter, here a selection

Winding shafts with continuous clamping bars are suitable for use in unwinding and rewinding, especially for winding multiple-ups. Special applications in the extruder area can also be realized.

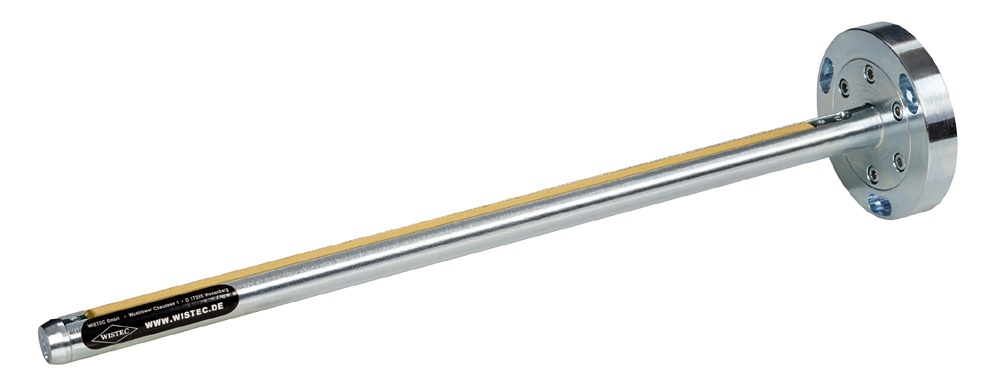

A number of applications in the processing industry require winding shafts with bearings on one side. These applications can also be easily realized with strip shafts. The favourable ratio of expansion length to total length is an advantage.

In case of higher roll weights it is helpful to make it easier for the operator to remove the roll. For this purpose roller conveyors are arranged between the expansion ledges. In the relaxed state they are in contact with the core inner diameter and the finished roll can be pushed down easily. Here is a practical example.