Regulation of the web edges

With the tension shafts with axial adjustment possibility developed by us, web edge corrections of +/- 15 mm can be realized without any problems, larger values on request.

Variant 1

At standstill and in set-up or inching mode, the knurled handle on the front face allows the shaft body with the roller to be moved axially. The set position is secured with the narrow knurled nut. The shaft can be actuated by means of a valve, as shown in the illustration or by a rotary seal. Other shaft diameters are possible.

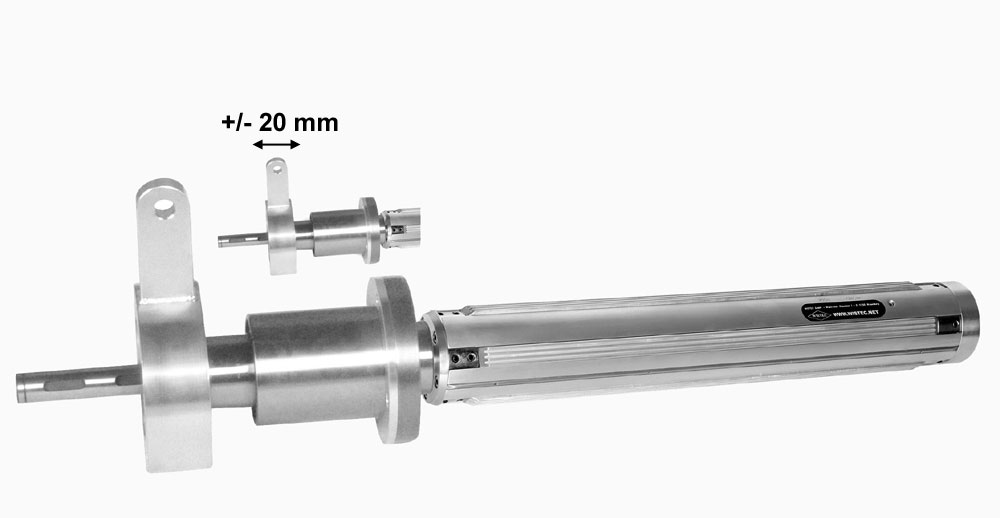

Variant 2

If the web correction is to be carried out continuously during operation, the following solution is suitable: The shaft is integrated into the machine concept by the flange bearing. During operation, a web correction of e.g. +/- 20 mm can be made by means of a coupled linear drive. Integrated in a control system, this solution can replace much more complex conventional systems.

Variant 3 - World novelty

This unique solution enables manual web correction while the machine is running. Regardless of the current speed, the operator can quickly and effectively correct the web edge. The rotary handle on the front side is decoupled from the shaft rotation. This means that the adjustment can be made at any time by turning it to the right or left.

The air shaft is connected to the machine frame via the left-hand mounting flange.

Even when the adjusting handle is actuated for the purpose of edge correction, the drive train, here with toothed belt, remains axially in position. The air is supplied via a rotary inlet or conventionally by means of a shaft valve.